12 milestones of 2012

December 26, 2012

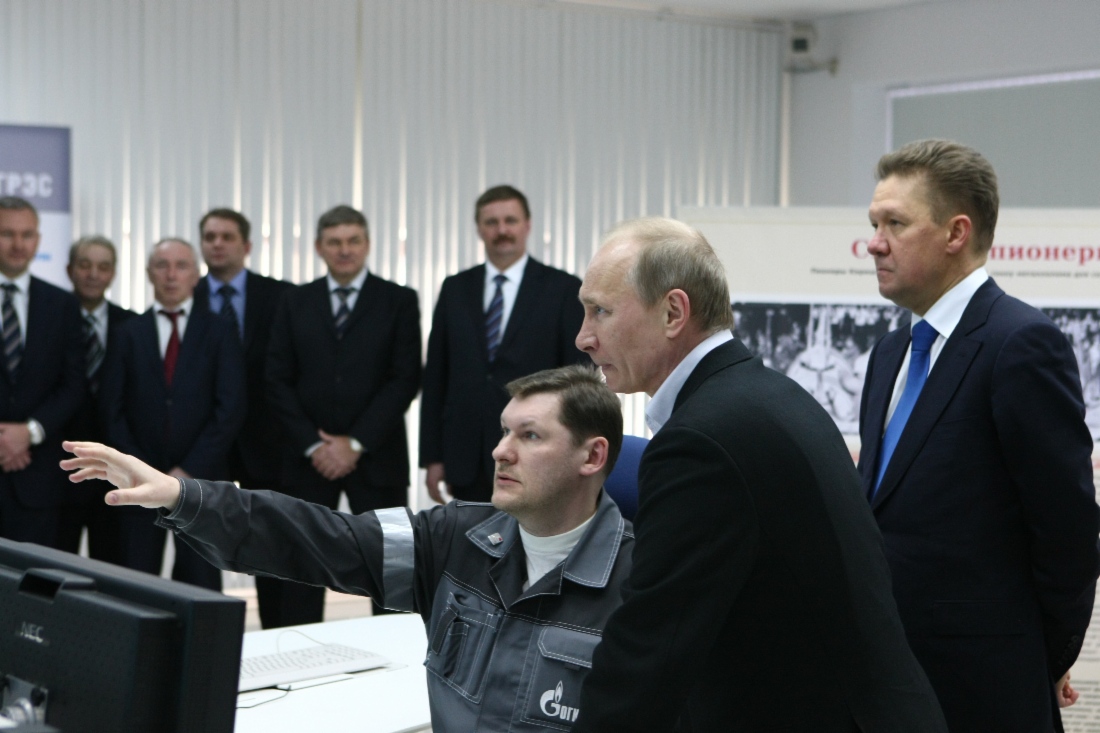

Launching gas supplies from Yamal

A new large gas production center – the Yamal Peninsula – appeared in Russia. It is an unprecedented project for the global gas industry. Not a single country in the world has ever created anything like this beyond the Polar Circle.

In October the first Yamal gas was delivered into the Unified Gas Supply System of Russia. The Bovanenkovo field with largest gas reserves on the Yamal Peninsula and the first string of the Bovanenkovo – Ukhta gas trunkline system stretching more than 1,240 kilometers were brought onstream. In 2017 it is planned to bring the field to its nominal capacity of 115 billion cubic meters of gas per year, which corresponds to approximately a sixth part of the present gas production in Russia.

By 2030 up to 360 billion cubic meters of gas will be annually produced from Yamal fields. In the nearest decades the increasing gas consumption in Russia and abroad will be satisfied mainly due to the Yamal gas.

Gazprom made the Peninsula a launching ground for using high-performance, secure and innovative technologies. Many of them were specially developed on Gazprom’s order for Yamal. For example, this is the first instance of gas transmission via onshore gas pipelines comprised of unique 1,420 millimeter pipes made of K65 (X80) high-strength and cold-proof steel with smooth interior coating at working pressure of 120 Ata.

Reaching historically high withdrawal rates in Gazprom UGS facilities

Improving the reliability of gas supplies to consumers is among Gazprom’s top-priority objectives. The Company constantly develops the gas transmission system and increases the capacity of underground gas storage (UGS) facilities being its integral part. The role of UGS facilities for ensuring reliable gas supplies is most noticeable during the heating period when they provide up to 20 per cent of gas supplies to consumers.

On December 20 during the abnormally cold weather period Gazprom reached the record daily withdrawal rate in the entire Russian UGS history – 670.7 million cubic meters of gas.

By expanding its UGS network, increasing the capacity and deploying the facilities closer to consuming centers, Gazprom enhances its ability to promptly respond to the demand growth. For instance, in Russia the Company builds up the potential of the Kasimovskoye, Kushchevskoye, Punginskoye, Sovkhoznoye and Stepnovskoye UGS facilities, constructs the Udmurtia Reserving Complex, the Kaliningradskoye, Volgogradskoye and Bednodemyanovskoye UGS facilities. In Europe – the Company’s major export market –the Haidach UGS facility in Austria and Banatski Dvor in Serbia were created, while the Katharina UGS facility in Germany and Bergermeer in the Netherlands are being built with Gazprom’s assistance.

Pushing ahead with gas industry development in Eastern Russia

Two gas production centers have already been established in Eastern Russia, namely, in Sakhalin and Kamchatka. In October Gazprom started developing another center in Yakutia. The final investment decision was adopted for a pre-development project of the prolific Chayandinskoye field and construction of the Yakutia – Khabarovsk – Vladivostok gas trunkline stretching approximately 3,200 kilometers. The processing facilities for the Chayanda gas will be built in the Belogorsk town (Amur Region). It is planned to start the gas production in 2017. The nominal capacity of the Chayandinskoye field makes up 25 billion cubic meters per year.

Gas production in Yakutia will evolve as a unified complex with production in the Irkutsk Region, whose gas resources will be put into production at the next stage. A powerful common gas transmission system will be created for these centers. According to the results of the contest held by Gazprom, the new gas transmission system was named the “Power of Siberia”.

A vast resource base of eastern fields makes it possible to establish in the region a new gas export center geared to the Asia-Pacific markets. At present, Gazprom is focused on liquefied natural gas (LNG) as a prioritized form of gas supplies to this region: an LNG plant with the annual capacity of at least 10 million tons will be built in Vladivostok. Moreover, the start of the Yakutia gas production center development made it possible to start negotiating the eastern route with China in addition to the western route of pipeline gas supplies.

Commissioning of second string of Nord Stream gas pipeline

On October 8 the celebrations dedicated to commissioning of the second string of the Nord Stream gas pipeline took place in the Portovaya Bay, the Baltic coast of Russia.

Nord Stream is a fundamentally new route for Russian gas export to Europe that directly connected the Russian largest gas fields and ultimate European consumers via the Baltic Sea. The gas pipeline is extremely significant for meeting the increasing natural gas demand in the European market.

Nord Stream comprises two strings stretching 1,224 kilometers and having the annual throughput of 27.5 billion cubic meters each. Both strings will be able to annually supply 55 billion cubic meters of gas for at least 50 years.

Construction of the first string was launched in April 2010 and completed in June 2011. Gas transmission started in the middle of November 2011. Placement of the gas pipeline’s second string started in May 2011 and finished in April 2012.

Launching construction of South Stream gas pipeline

On December 7 the Russkaya compressor station site (near Anapa, Krasnodar Territory) hosted the celebrations dedicated to the South Stream gas pipeline construction start-up.

The South Stream project is aimed at strengthening the European energy security. This is the key project within the strategy to diversify gas supply routes to the EU. The total length of the offshore section will be 925 kilometers, the onshore section – 1,455 kilometers, the maximum water depth of pipes laid on the sea bottom – more than two kilometers and the design capacity – 63 billion cubic meters.

The South Stream starts from the Russian Black Sea coast near Anapa and runs through the Black Sea to the coast of the Republic of Bulgaria (925 kilometers). Natural gas will be further conveyed via Bulgaria, Serbia, Hungary and Slovenia to northern Italy. Gas laterals will be built to Croatia and Republika Srpska.

In order to feed the required amount of gas to South Stream, Russia’s gas transmission system throughput is expected to be increased through the construction of additional 2,446 kilometer linear section and 10 compressor stations with the total capacity of 1,516 MW. This project was named Southern Corridor and will be implemented in two phases.

he Russkaya compressor station, the most powerful one in the world, will be the Southern Corridor end point and the South Stream start point at the same time. The station will provide for building gas pressure enough to convey the blue fuel along the South Stream offshore section without additional technical means.

South Stream Transport is in charge of constructing the South Stream offshore section. The company has the following shareholding structure: Gazprom – 50 per cent, Eni – 20 per cent, Wintershall Holding and EDF – 15 per cent each. Henning Voscherau is the Chairman of the South Stream Transport Board of Directors. With a view to implement the gas pipeline onshore section in Central and Southern Europe, Gazprom and the company’s regional partners created the joint project companies in Bulgaria, Serbia, Hungary and Slovenia.

Commissioning of the gas pipeline and the launch of commercial gas supplies are scheduled for December 2015.

Allocating record amount of investments for Russian regions gasification

Gazprom continues to actively develop one of its prioritized activities in the domestic market – gasification of Russian regions. In 2012 investments hit the record high level of about RUB 33.8 billion. It enabled to construct 235 inter-settlement gas pipelines with the total length of about 3.4 thousand kilometers in 42 regions of the country. Natural gas was for the first time supplied to 429 population centers, which means that one more gasified locality appeared in Russia every day. More than 54 thousand apartments and households were converted to natural gas.

Gazprom aims at reaching the highest economically viable level of gasification in Russia. In this respect, one of the Company’s most important long-term objectives is gasification of Eastern Siberia and the Far East along with creating gas production and transmission infrastructure in these regions.

Reaching new level in NGV fuel expanded use in Russia

In 2012 the work started on advancing the Russian NGV fuel market to a completely new level of development.

Gazprom sent proposals on joint development of the NGV infrastructure to 69 regions of the country. As of late December 2012, 54 regions were ready to confirm their commitment to convert vehicles to compressed natural gas (CNG) (or purchase them) by the time when the construction of CNG filling stations is finished.

The sections on natural gas use as a motor fuel and on the appropriate infrastructure development will be mandatory both in the Russian Regions Gasification Program and corresponding regional documents.

Natural gas remains the most environmentally friendly fuel. Its active use will significantly reduce emissions of harmful substances into the atmosphere and improve the environmental situation in population centers.

The expansion of natural gas use in motors will allow Gazprom creating a new promising gas sales market in Russia. Acquiring a fuel which is cheaper in comparison with gasoline and diesel will enable the regions to save significantly on transportation costs, as well as on the use of equipment in the agricultural sector.

Gazprom Gazomotornoye Toplivo has been identified as the company that will consolidate Gazprom Group’s assets related to NGV fuel production and sales.

Successfully completing world’s first LNG supply via Northern Sea Route

The Ob River LNG carrier chartered by Gazprom Group successfully completed the world’s first LNG supply via the Northern Sea Route (NSR).

The carrier left the Port of Hammerfest (Norway) on November 7; from November 9 to 18 it sailed across the NSR escorted by Atomflot-owned atomic icebreakers. During the first half of the voyage, between the Barents Sea and the Kara Sea, there was not much ice in the waters, but during the second half of the passage, from the Vilkitski Strait to the Bering Strait, the carrier was headed through young ice with the thickness reaching 30 centimeters. The voyage was accomplished safely and fully in accordance with schedule. On December 5 the carrier arrived at the Port of Tobata delivering a Gazprom Group-owned LNG cargo to Japanese consumers.

The successful voyage of the Ob River LNG carrier makes it possible to supply Russian LNG to Asia-Pacific and the European market via the NSR.

The Northern Sea Route is the strategic route, which enables to reduce trip time from northern Europe to northeast Asia by almost 40 per cent, compared with the routes via the Suez Canal or the Panama Canal. Thus, using the NSR as the supply route allows saving fuel, reduce losses from LNG evaporation, increasing volumes of delivered gas, reducing CO2 emissions and mitigating risks of conflicts and pirate attacks during the voyage.

Signing basic asset swap agreement between Gazprom and Wintershall

On November 14 Gazprom and Wintershall signed a legally binding basic agreement on asset swap, which provides for major terms and conditions for the asset swap deal under the project for joint development of the Achimov deposits in the Urengoy oil, gas and condensate field. The final agreements are expected to be inked in 2013.

According to the document, Wintershall may acquire 25 per cent plus one share in the new joint venture on developing blocks 4A and 5A in the Achimov deposits of the Urengoy field.

In addition, the agreement provides for Gazprom to receive a 50 per cent stake in WINZ, which runs natural gas exploration and production projects in the North Sea, and increase its stakes in gas trading and storage companies of WINGAS Group to 100 per cent, as well as in WIEH and WIEE – to 100 per cent.

In July 2003 Gazprom and Wintershall set up the Achimgaz joint venture to develop the first pilot block of the Achimov deposits in the Urengoy field. In 2008 Achimgaz brought the block into pilot operation.

Joining licensed blocks development project offshore Vietnam

On April 5 Gazprom and PetroVietnam signed the Agreement on the Russian Company involvement in the joint development project for Licensed Blocks 05.2 and 05.3 offshore Vietnam in the South China Sea.

The document stipulates that Gazprom will obtain a 49 per cent stake in the Production Sharing Agreements that set forth the conditions required for implementing the project.

Two gas and condensate fields – Moc Tinh (Block 05.3) and Hai Thach (Blocks 05.2 and 05.3) as well as the Kim Cuong Tay oil field (Block 05.2) were discovered within the blocks. The aggregate reserves of the two gas and condensate fields are evaluated at 55.6 billion cubic meters of gas and 25.1 million tons of gas condensate. It is planned to construct 16 production wells 2,000 to 4,600 meters deep in order to develop the fields.

Participation of Gazprom in the development of these fields makes it possible to expand the cooperation with the Vietnamese party and strengthen the Company’s position in the strategically important and dynamic region as South-East Asia.

Complying with more than half of new power generation capacities commitment

In March Gazprom commissioned a combined cycle gas turbine unit (CCGT-800) with the capacity of 800 MW at the Kirishi SDPS. It is the largest heat generating facility which has been commissioned over the last 30 years. It has become the combined cycle gas turbine unit of the highest power capacity in the country.

CCGT-800 is a unique project for Russia. Power generating unit No.6 (commissioned back in 1975) was upgraded and two brand new heat recovery boilers were built over the existing steam turbine. The power generating unit efficiency rose from 38 per cent to 55 per cent. It was the first time in the history of the domestic power industry when large-scale efforts had been made to retrofit the existing power generating unit.

Starting from 2007, with the CCGT-800 commissioning, Gazprom has complied with more than a half of the assumed commitments on new power generation capacities commissioning.

Gazprom’s task is to increase efficiency of the existing capacities up to the level of the world’s largest energy companies.

Continuing successful development of oil business

In 2012 Gazprom Neft, Gazprom’s subsidiary company started simultaneous oil production from two fields in the Yamal-Nenets Autonomous Area: Messoyakhskoye and Novoportovskoye.

In addition, Gazprom Neft went on rapidly upgrading its refineries. As a result, the company will fully switch to production of the Euro 4 and Euro 5 standards gasoline starting from 2013 – two years before the deadline set by the Russian Government. The company’s another goal is to improve the oil refining efficiency.

Gazprom Website Editorial Board